Submission Deadline

28 February 2026

Judging

Date

24 & 25 March 2026

Winners Announcement

22 April 2026

28 February 2026

24 & 25 March 2026

22 April 2026

Welcome to our engaging series about distillers and their art. In this chapter, meet Dr. Kit Carruthers, the owner and distiller of Ninefold Distillery. From environmental geochemist to rum distiller, Dr. Carruthers' path is both fascinating and inspiring. Discover his tale and ideas in our unique interview, which continues below.

By training, I'm an experimental environmental geochemist with experience in climate change-related research activities, environmental consultancy and geotechnical engineering. This is really to say that I spent a lot of time as a student - three degrees - and not a lot of time deciding what I wanted to do with my life. After I finished my PhD in Carbon Capture and Storage in 2016, I moved back home to Dumfries & Galloway. Faced with the inheritance from my father of our ancient family estate, I took an opportunity to invest some family money in renovating a couple of old dilapidated farm buildings, to repurpose as a rum distillery and diversify the estate business. I did this with no experience in the industry whatsoever and so largely relied initially on contacts I'd made and sheer naive gumption!

I am the owner, and being only a two-full-time employee operation, my day is multifaceted, to say the least. I don't have a typical daily routine, but my role involves everything from top-level business planning, management, finances, marketing, order fulfilment and sales, down to being responsible entirely for production (fermentation, distilling, casking, bottling). And all the rest! I usually work long hours and most weekends, but in 2024 I'm going to attempt a better work/life balance. Hah!

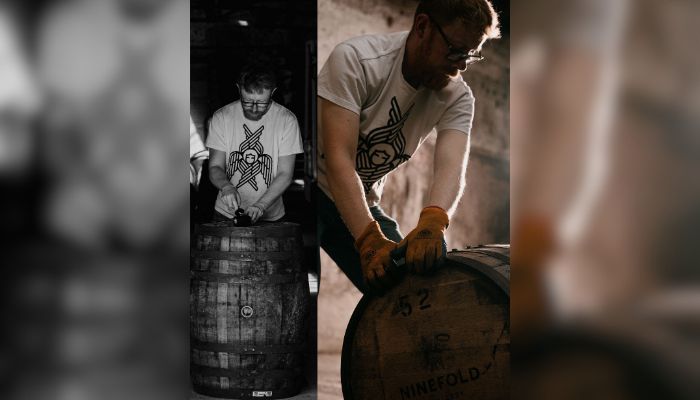

Image: Dr. Kit Carruthers

The craft gin and beer scenes kicked off during my time as a PhD student in Edinburgh, and so saw the rise of brands like Edinburgh Gin, Pickerings, Brewdog etc. Although I didn't know it at the time, I was drawn to the idea of a hands-on creative but scientific job where I worked for myself, and so there was a lot of appeal in distilling my booze. It just seemed a cool and rewarding (and money-making) thing to do.

Resourcefulness, attention to detail, a firm belief in your abilities and limits, willingness to just get stuck in, and not being afraid to try things out, experiment and push what your equipment can do. It helps to have a reasonably good palate too!

As the owner/distiller in a micro-business, the responsibility for creating the product, marketing and selling is all wrapped up together. My brand is largely built around me, as the owner, and I'm not shy of putting myself front and centre alongside my products. It's hugely important for a business like mine that consumers can connect directly to the heart of the operation. It fosters loyalty and with that comes customers who become ambassadorial for the brand i.e. free marketing! But I also really enjoy meeting the people who buy and drink my rum.

Attention to detail, curiosity, resourcefulness, and humility.

For me, it's keeping on top of everything. There's a huge juggling act going on behind the scenes of what the public sees, and it's making sure that you don't drop the 'make the spirit good' ball. So, maintaining consistency and quality of product, while also being pulled in many other directions, is the hardest part for me.

We're a micro-rum distillery based in Scotland, making our rum from scratch for nearly 5 years. We pride ourselves in our high-quality and versatile portfolio of rums; unaged (aka white) rum, spiced rums and aged rums. Little Red Door in Paris made their house mojito with Ninefold Pure Single Rum, we're on the back bar at world-class bars in London, Edinburgh and Glasgow, and were the first UK rum brand to get an exclusive cask release with The Whisky Exchange. Can I pour you a few samples?

The double whammy of the cost of living crisis plus the Government's decision to hike the duty rate on spirits by over 10% is having a real cooling effect on our direct-to-consumer sales. The duty rate in particular is stifling growth for small indies like myself, and which comes on top of high energy costs and increasing material costs. Having to pass that on to consumers makes it challenging to then sell volumes needed for profit, particularly when a business like mine is based rurally and local incomes are lower. But things seem to be settling now, energy prices are coming down so hopefully we're seeing a route out of this.

Image: Dr. Kit Carruthers

Working a four-day week, and spending the rest of the time enjoying good food and drink!

It has to be the daiquiri. A classic that can be enjoyed anywhere, anytime. Although right now, at home with the cat in front of the fire, is where I'm most enjoying a drink.

[[relatedPurchasesItems-63]]

N/A / I don't read books related to my industry.

All of our waste (i.e. anything not used as muck or dunder) gets loaded on a trailer and carted off to an anaerobic digestor about 7 miles away, where it's used to help lubricate the internal chambers of the digestor tank.

See bartender pitch!

I use backset/dunder from stripping distillation runs in the next fermentation, adding a small amount of extra character to the batch. I use two different yeasts, and yeast nutrients, which all contribute in their way to the complexity of the wash. For some specific batches, I've been experimenting with the use of muck - fermenter tank washings left to 'mature' outside in a tank - which has been a little hit and miss-so far. More research is needed.

Image: Dr. Kit Carruthers

When the distillery was built in a converted milking shed, the refurbishment involved a doubly-insulated building fabric, double glazing, central heating and solar panels. Our heating bills are minimal, and our day-to-day non-production electricity costs are met with solar PV on the roof. Our production is all-electric, meaning we can buy electricity from renewable-only tariffs, and we utilise energy-saving measures in our production such as the use of a backset in pre-heating fermentations. We switched to a bespoke glass bottle in 2022 which saved around 35% in weight, and we use no plastics in our bottle packaging or shipping.

I'm very fixed on what I do, which is to make rum and make it the best I can. I'm not an opportunistic distiller who's going to be looking at the next trend and having a go at that too to bulk out my portfolio. You hear rumours and opinions on things like low/no alcohol, tequila, etc., but so long as rum keeps a steady ship then I don't look at what's next.

(Index Image Credits: Joe Brayford)

Show your spirits where it matters. Get your products tasted by top bartenders, buyers and experts at the London Competitions — enter now.